02.

Loose Lay

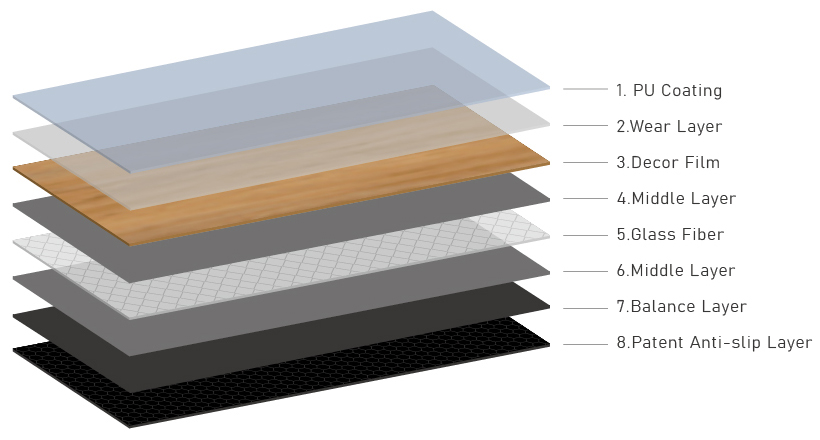

Winton Looselay integrates our patent emboss with outstanding R10 level resistance.

Ideal wet surface appliance and superior dimensional stability to accommodate any commercial area.

Data Specification

| Characteristic | Test Method | Specification |

|---|---|---|

| Appearance(standard master sample) | Visual | The surface to be free of defects |

| Length Tolerance | ISO 24341 | Deviation < 0,15 % of nominal length |

| Width Tolerance | ISO 24341 | Deviation < 0,15 % of nominal length |

| Total thickness | ISO 24346 | Nominal±0.3mm |

| Squareness and straightness | ISO 24342 | ≤0.25mm |

| Residual Indentation | ISO 24943-1 | <0.3mm |

| Flexibility | Test using a 20 mm mandrel. For products which show signs of cracking |

|

| Dimensional Stability -- MD/AMD | ISO 23999 | ≤ 0.25% |

| Colorfastness | ISO105-B02 blue | ≥ 6/Δ E≤8 |

| Castor test | ISO 4918 | After 25 000 cycles, no delamination shall occur. |

| Curling After exposure to heat |

ISO 23999 | ≤2mm |

| Slip Resistance | DIN 51130 | ≥ R9 |

| Bottom layer Coefficient of friction |

ASTM D 1894-14 | < 1.2 DRY |

| Fire Resistance | ISO9239-1(5) ISO11925-2 (8) |

Bfl.S1 PASS(≥8.0kW/m²) (Fs≤150mm within 20s) |

| Heavy metals free | En71-part 3 | Pb, Hg,Cr,As, Sb,Ba,Se,Cd free |

LOOSELAY-TILE

-

914mm*914mm -

609.6mm*304.8mm -

457.2mm*457.2mm -

914.4mm*457.2mm -

914.4mm*609.6mm

LOOSELAY-PLANK

-

1219.2mm*152.4mm -

1227mm*184mm -

1219.2mm*228.6mm -

914.4mm*152.4mm